Our capabilities

World-class facilities for serial production. In Europe.

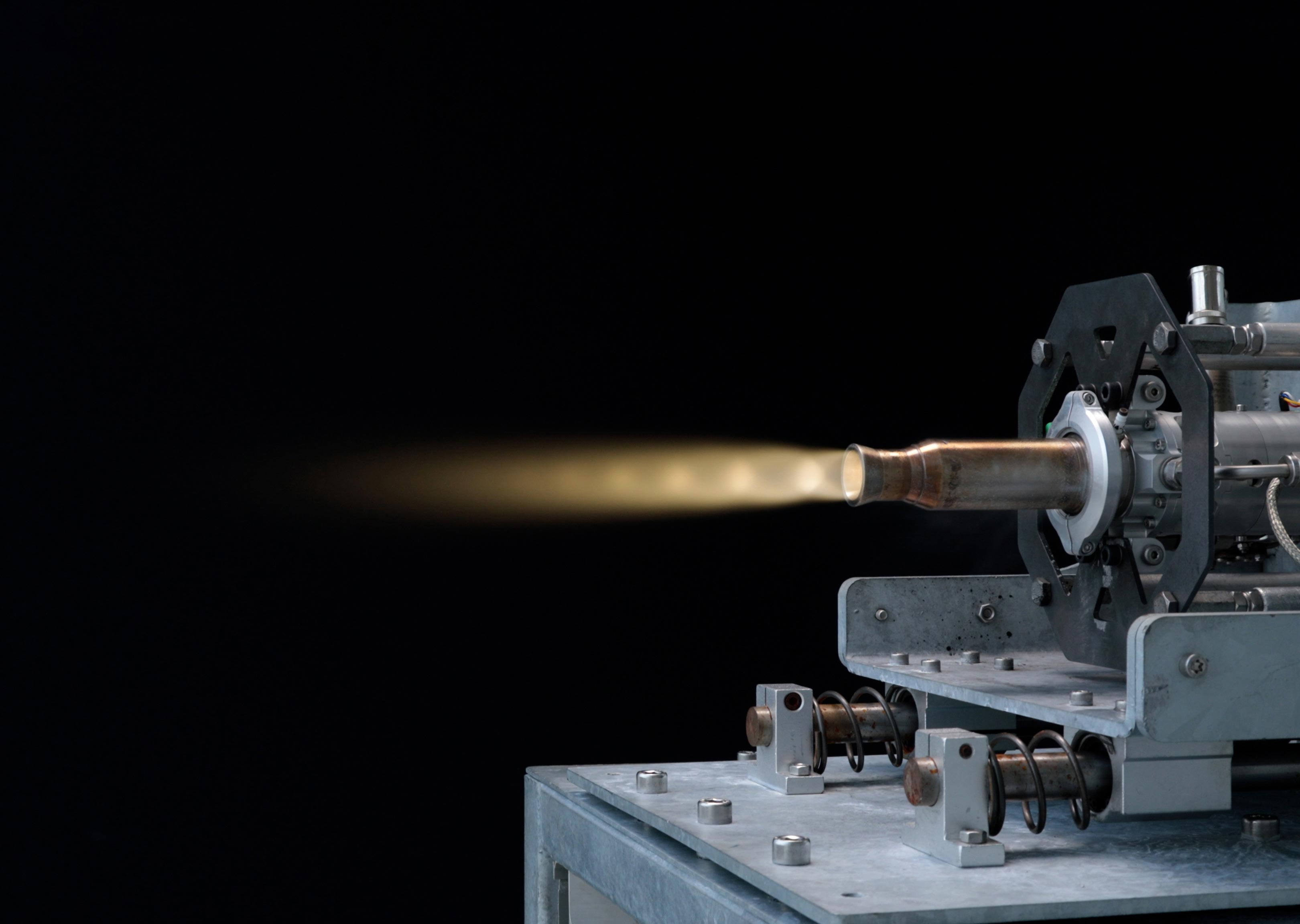

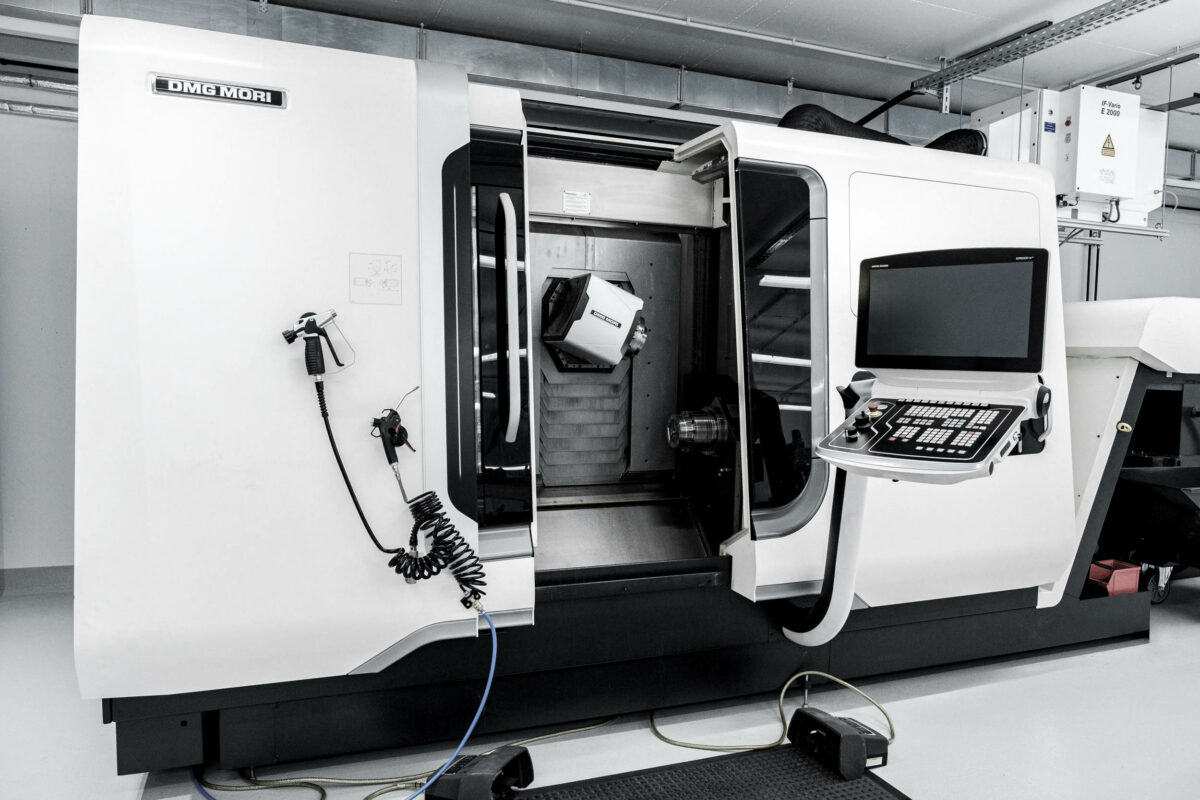

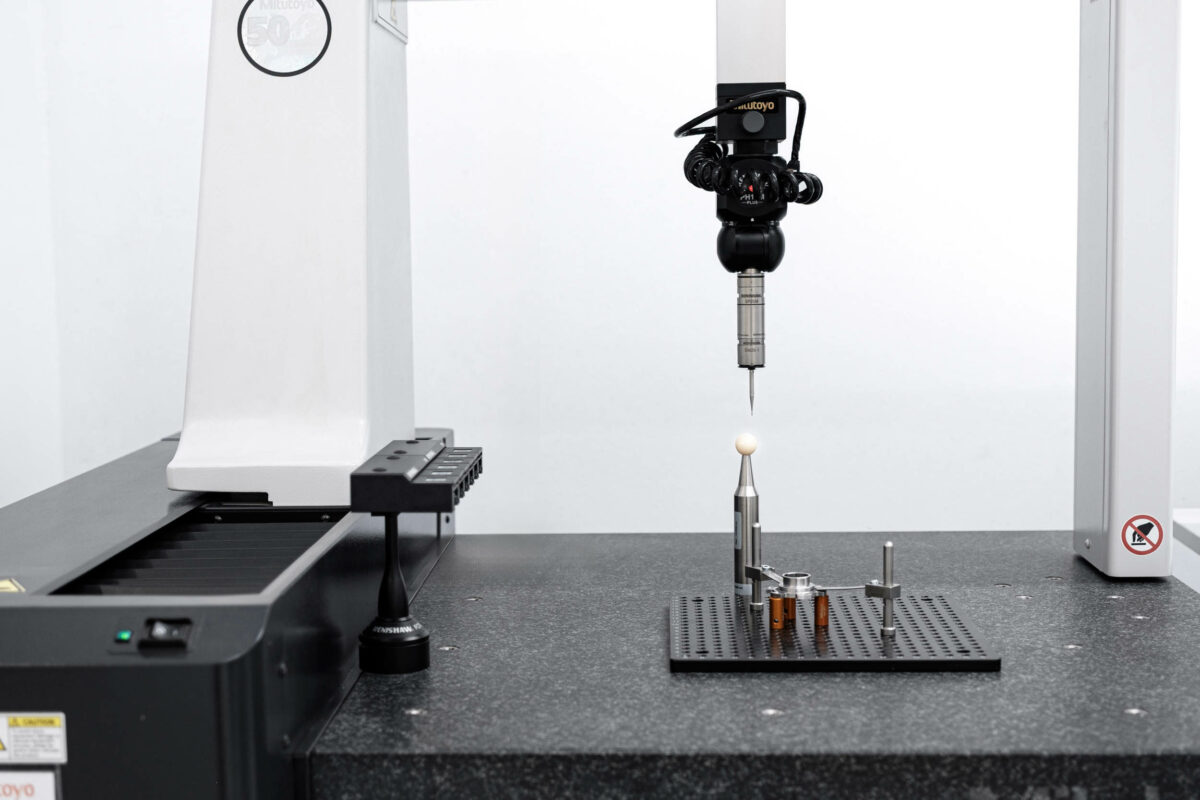

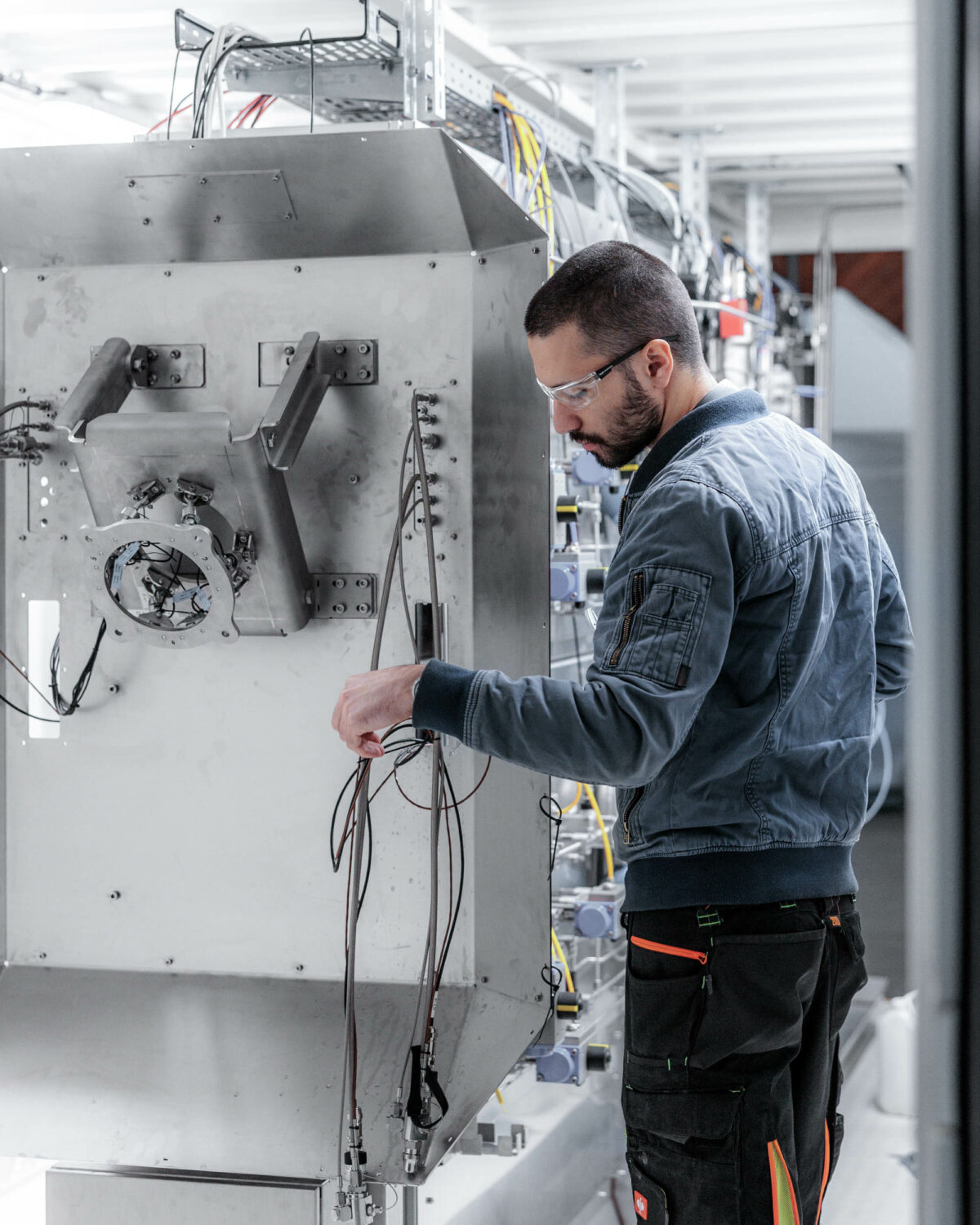

We operate a 560 m² high-precision production facility and Europe’s most advanced commercial test site for high-thrust mobility systems, optimized for rapid development and scalable production. With a 98% European supply chain and full in-house control of critical technologies, every product is designed, built, and qualified on-site — from engineering and CNC machining to assembly in our ISO 8 clean room and testing at our high-performance vacuum facilities.